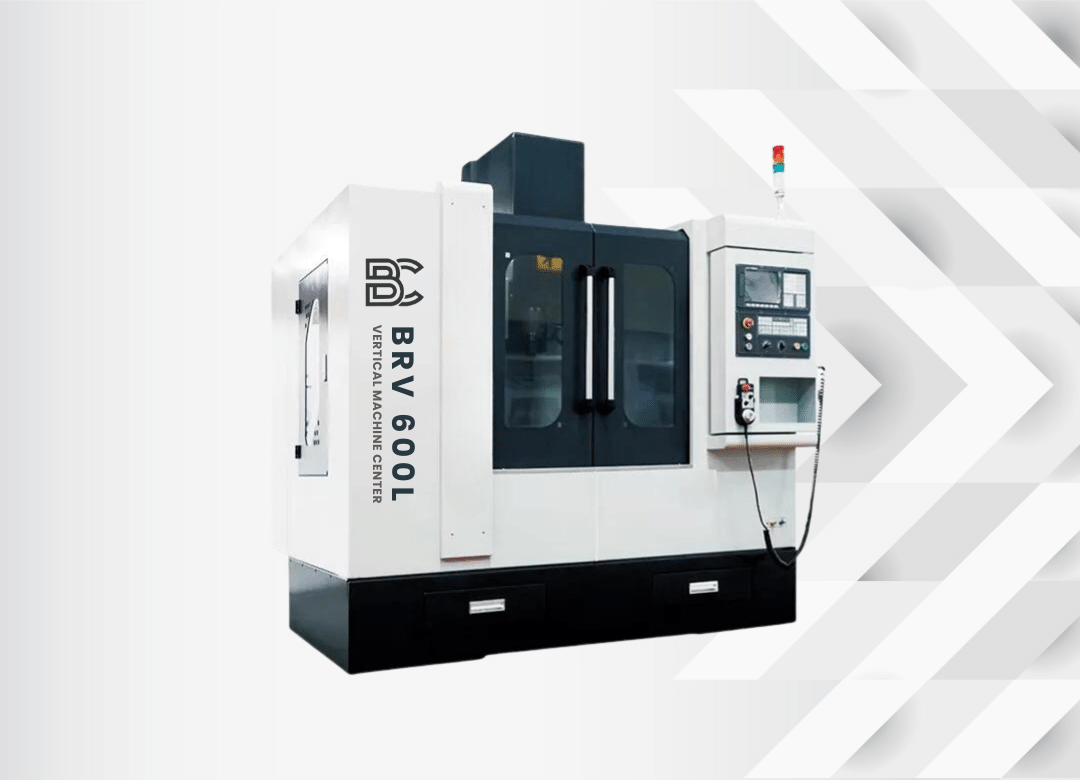

| BRV 600L | |

| WORKTABLE | |

| Worktable size (L×W) | 800x400mm |

| T-slots size (N×W×D) | 3-14x100mm |

| Max. loading of worktable | 300kg |

| TRAVEL | |

| X/Y/Z axis travel | 600/400/450mm |

| MACHINING RANGE (DISTANCE FROM) | |

| Spindle center to column | 550mm |

| Spindle nose to worktable surface | 100-550mm |

| SPINDLE | |

| Spindle taper | BT40 |

| Spindle power | 5.5kw |

| Max. spindle speed | 8000rpm |

| FEED | |

| Max. feed speed | 10m/min |

| Rapid feed speed (X/Y/Z) | 30/30/25m/min |

| BALL SCREW (DIAMETER&LEAD) | |

| X/Y/Z axis ball screw | 3210 |

| TOOL MAGAZINE | |

| Tool magazine capacity | 12T/16T(optional) |

| Max. length of tool | 300mm |

| Tool change time | 7s/2.5s |

| POSITIONING ACCURACY | |

| Positioning accuracy (X/Y/Z) | ±.0.005mm |

| Re-positioning accuracy (X/Y/Z) | ±.0.003mm |

| MACHINE DIMENSION | |

| L×W×H | 1900x1700x2240mm |

| Machine weight | 3500kg |

VMC600L CNC Vertical Machining Center 3 Axis Linear Guideway

All 3axis use class C3 precision screw,match up the nut preloading and screw prestretched,preeliminate backlash and temperature rise,so that the machine can achieve stability of the positioning and repeatability accuracy.Besides,the X/Y/Z axis use precision linear rails to ensure the control of the positioning accuracy and processing errors,so that the machine can have high accuracy and long working life.

Standard Equipment

Servo motor spindle BT40, 7Kw, s=10000rpm

worktable size:400x800mm; X/Y/Z: 600X400X450mm,

umbrella type ATC: 12T, X/Y/Z Linear guideway